Abstract

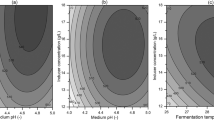

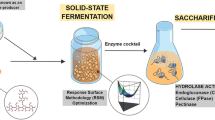

Naringin, considered as the main bitter component of grapefruit, requires the use of enzymes to reduce the level of this substance during juice processing. For this reason, it has been the focus of many studies. In this study, to increase the production of naringinase by Aspergillus niger cultivated in solid-state fermentation (SSF), a three-component simplex-centric mixing design along with a response surface methodology (RSM) was applied to generate statistical models and analyze the dataset. First, grapefruit peel, rice bran, and wheat bran were used for substrate selection for naringinase production and, finally, selected the best of the three inducers or their mixtures to remove the bitterness of grapefruit juice. Cultivation with 2.3 g of grapefruit peel, 2.5 g of rice bran, and 5.2 g of wheat bran and medium supplementation with a mixture of naringin, rutin, and hesperidin in the concentration of 2, 5, 4.5, and 3.0 g/L, respectively, resulted in a maximum activity of 28 U/mL. The results indicate that the sequencing procedure, which allowed the definition of an optimal mixture of components, is a new way for microorganisms to have a high naringinase yield, in particular by SSF, since our data showed a 96% increase in the production of naringinase. This dataset can help other researchers apply a mixing design to increase enzyme production.

Similar content being viewed by others

Data availability

Not applicable.

References

Puri M, Kaur A, Barrow CJ, Singh RS (2011) Citrus peel influences the production of an extracellular naringinase by Staphylococcus xylosus MAK 2. App Microbiol Biotechnol 89:715–722

Puri M, Banerjee U (2000) Production, purification, and characterization of the debittering enzyme naringinase. Biotech Adv 3:207–217

Purewal SS, Sandhu KS (2021) Debittering of citrus juice by different processing methods: a novel approach for the food industry and agro-industrial sector. Scientia Horticulturae 276:109750. https://doi.org/10.1016/j.scienta.2020.109750

Awad GEA, Abd El Aty AA, Shehata AN, Hassan ME, Elnashar MM (2016) Covalent immobilization of microbial naringinase using novel thermally stable biopolymer for hydrolysis of naringin. Biotech 6:14. https://doi.org/10.1007/s13205-015-0338-x

Srikantha K, Kapilan R, Seevaratnam V (2016) Optimization of naringinase production from Aspergillus flavus in solid-state fermentation media using citrus peel as support. Scholars Acad J Biosci 4(6):535–543. https://doi.org/10.21276/sajb.2016.4.6.16

Ribeiro MH (2011) Naringinases: occurrence, characteristics, and applications. Appl Microbiol Biotechnol 90(6):1883–1895. https://doi.org/10.1007/s00253-011-3176-8

Bodakowska-Boczniewicz J, Garncarek Z (2020 ) Immobilization of naringinase from Aspergillus niger on a magnetic polysaccharide carrier. Molecules 25(12):2731. https://doi.org/10.3390/molecules25122731

Zhang L, Xu X, Jiang T, Wu K, Ding C, Liu Z, Zhang X, Yu T, and Song C (2018) Citrus aurantium naringenin prevents osteosarcoma progression and recurrence in the patients who underwent osteosarcoma surgery by improving antioxidant capability. Oxid Med Cell Longev 1–16. https://doi.org/10.1155/2018/8713263

Patil SV, Koli SH, Mohite BV, Patil RP, Patil RR, Borase HP, Patil VS (2019) A novel screening method for potential naringinase-producing microorganisms. Biotechnol Appl Biochem 66(3):323–327

Zhu Y, Jia H, Xi M, Li J, Yang L, Li X (2017) Characterization of a naringinase from Aspergillus oryzae 11250 and its application in the debitterization of orange juice. Process Biochem 62:114–121. https://doi.org/10.1016/j.procbio.2017.07.012

Karuppaija S, Kapilan R, Seevaratnam V (2016) Optimization of naringinase production by Rhizophus stolonifer in solid state fermentation media using paddy husk as support. Scholars Acad J Biosci 4(6):507–514

Housseiny MM, Aboelmagd HI (2019) Nano-encapsulation of naringinase produced by Trichoderma longibrachiatum ATCC18648 on thermally stable biopolymers for citrus juice debittering. J Microbiol 57(6):521–531. https://doi.org/10.1007/s12275-019-8528-6

Ni H, Chen F, Cai H, Xiao A, You Q, Lu Y (2012) Characterization and preparation of Aspergillus niger naringinase for debittering citrus juice. J Food Sci 77:1–7. https://doi.org/10.1111/j.1750-3841.2011.02471.x

Mukund P, Belur PD, Saidutta MB (2013) Production of naringinase from a new soil isolate, Bacillus methylotrophicus: isolation, optimization and scale-up studies. Prep Biochem Biotech 44(2):146–163. https://doi.org/10.1080/10826068.2013.797910

Borkar V, Chakraborty S, Gokhale JS (2020) Fermentative production of naringinase from Aspergillus niger van Tieghem MTCC 2425 using citrus wastes: process optimization, partial purification, and characterization. Appl Biochem Biotechnol. https://doi.org/10.1007/s12010-020-03385-9

Cornell JA (2002) Experiments with mixtures: designs, models and the analysis of mixture data, 3rd edn. John Wiley and Sons, New York

Statsoft, Inc. Statistica (data analysis software system), version 7. 2007. <www.statsoft.com>

Thammawat K, Pongtanya P, Juntharasri V, Wongvithoonyaporn P (2008) Isolation, preliminary enzyme characterization and optimization of culture parameters for production of naringinase isolated from Aspergillus niger BCC 25166. Nat Sci 42:61–72

Saravitz DM, Pharr DM, Carter TE (1987) Galactinol synthase activity and soluble sugars in developing seeds of four soybean genotypes. Plant Physiol 83:185–189

Dubois M, Gilles KA, Hamilton JK, Rebers PA, Smith F (1956) Colorimetric method for determination of sugars and related substances. Analytical Chem 28:350–356

Mendoza-Cal A, Cuevas L, Lizama-Uc G, Ortiz-Vazquez E (2010) Naringinase production from filamentous fungi usign grapefruit rind in solid state fermentation. African J Microbiol Res 4:1964–1969

Bram B, Solomons GL (1965) Production of the enzyme naringinase by Aspergillus niger. Applied Microbiol 13:842–845

Shanmugaprakash M, Vinoth-Kumar V, Hemalatha M, Pothiyappan-Karthik VM (2011) Solid-state fermentation for the production of debittering enzyme naringinase using Aspergillus niger MTCC 1344. Eng Life Sci 11:322–325

Silva CS, Bovarotti E, Rodrigues MI, Hokka CO, Barboza M (2009) Evaluation of the effects of the parameters involved in the purification of clavulanic acid from fermentation broth by aqueous two-phase systems. Biopro Biosys Eng 32:325–632

Norouzian D, Hosseinzadeh A, Inanlou DN, Moazami N (2000) Production and partial purification of naringinase by Penicillium decumbens PTCC 5248. W J Microbiol Biotechnol 16:471–473

Mateles RI, Perlman D, Humphery AE, Deindorfer FH (1965) Fermentation review. Biotechnol Bioen 7:54–58

Puri M, Kaur A, Singh RS, Singh A (2009) Response surface optimization of medium components for naringinase production from Staphylococcus xylosus MAK2. App Biochem Biotechnol 162:181–191

Kumar VV (2010) Comparative studies on inducers in the production of naringinase from Aspergillus niger MTCC 1344. African J Biotechnol 9:7683–7686

Fukumoto J, Okado S (1973) Naringinase production by fermentation. Japanese Patent 7306554.

Custodio MVG, Otamendi FP, Vidal DR, Alventosa SV (1996) Production and characterization of an Aspergillus terreus α-L-rhamnosidase of oenological interest. Lebensm Unters Forsch 203:522–527

Bokkenheuser VD, Shackleton CHL, Winter J (1987) Hydrolysis of dietary flavonoid glycosides by strains of intestinal bacteroides from humans. Bioch J 248:953–956

Petri AC, Buzato JB, Celligoi MA, Borsato D (2014) Optimization of the production of α-L-rhamnosidase by Aspergillus niger in solid state fermentation using agro-industrial residues. Brit Microbiol Res J 4:1198–1210

Acknowledgements

The authors would like to extend their sincere appreciation to the UEL and UNESP for their support and CAPES for funding this work and scholarships. We would like to thank the coordinated Plant Molecular Biology Laboratory of FCAV/UNESP by Eliana G.M. Lemos.

Funding

The authors would like to extend their sincere appreciation to the CAPES for funding this work.

Author information

Authors and Affiliations

Contributions

Fernanda de Oliveira: research conceptualization, data curation, investigation and methodology, writing. Tereza Cristina Luque Castellane: HPLC investigation and methodology, review and editing. Marcelo Rodrigues de Melo and João Batista Buzato: research conceptualization and supervison.

Corresponding authors

Ethics declarations

Conflict of interest

The authors declare no competing interests.

Additional information

Publisher's note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

de Oliveira, F., Castellane, T.C.L., de Melo, M.R. et al. Preparation of Aspergillus niger 426 naringinases for debittering citrus juice utilization of agro-industrial residues. Int Microbiol 25, 123–131 (2022). https://doi.org/10.1007/s10123-021-00199-5

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10123-021-00199-5